Big, rustic, heavy hall table.

A friend/neighbor referred over a new customer. She saw a cool table on Instagram and wanted something similar in her home. Here is the image they sent me.

She wanted a seven foot long beam that was 11" x 11". With two 25" legs also 11" x 11". Making the height of the overall table 36".

I recently did a beam for another customer and knew the process wouldn't take too long to cut. I quoted a price that I thought was reasonable and told her I would get back to her ASAP.

I thought it would be best to do it all from one log so everything matched. I had a sixteen foot log out in the yard that ended up being perfect.

I cut the log into a five foot section and an eight foot section. I wasn't really sure how I was going to cut the ends off strait. So I figured I better have a little extra length so I could make a mistake and it not matter.

Milling the legs was pretty easy. I made the beam first. Then rough cut each leg with the chainsaw. Then carefully cut the ends off at 25" with the mill. But that is when the weight of this project got all real on me?! I grabbed a scale from the house and weighed one of the legs.

Each leg was just over 110 pounds! So let's break out the math. We'll say each foot of the 11" x 11" block is 55 pounds. The top beam is 7 foot and each leg is roughly 2 foot. That makes it 11 foot long, times 55 pounds and you are looking at just over 600 pounds!! Holy crap?!

I called the customer and gave her the total weight. She was as surprised as I was. I told her I would cut the top beam and she could come over to decide if this was really what she wanted.

The customer and her husband came over to see the beams. I think the were kind of blown away by the size and the beauty of the wood. We brainstormed all of our options to reduce the weight. Her original plan was to have this behind a couch. But we were afraid that it would be too top heavy and fall if it was accidentally knocked over. After much discussion we decided to cut an extra foot off the top beam and move the location in her house to a wall where it could be anchored to the studs.

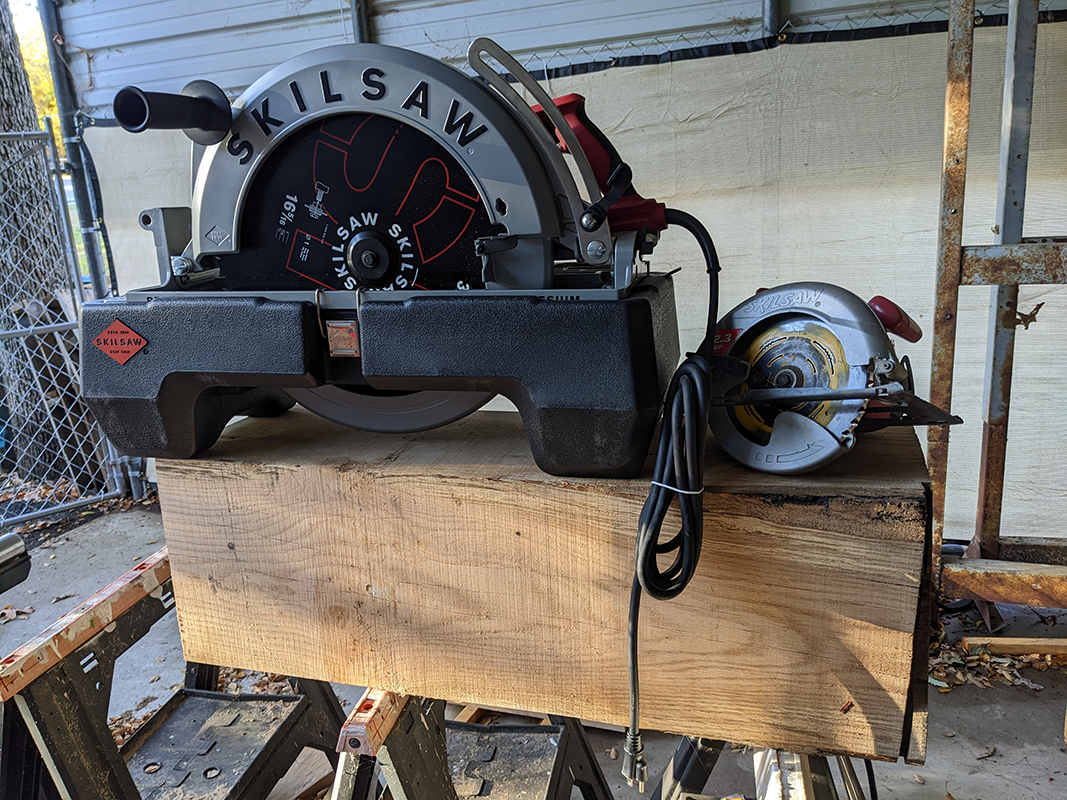

That is when I ran into another issue. The legs could easily be turned upright and milled to a specific size. But I couldn't do that with a six foot long block. So I set up my cookie jig on the trailer again and cut one end. It was pretty good (you will see in the final picture that the trailer was not level, so there is a little slant to it). But then we decided to buy a new tool that we had been eyeing. A timber framing circular saw.

What a beast! This circular saw has a blade just over 16" in diameter. You see the typical circular saw in the picture above. It looks tiny compared. So the last cut on the top block was perfectly strait.

Next was the delivery process. It took an appliance dolly, moving straps, and four grown men to move everything into place. I added non-slip pads under the feet. Counter sunk four holes per leg and drilled pilot holes with a 12" bit. Then screwed 14" timber framing screws (the kind you can't buy at Lowes or Home Depot) to hold everything together.

The whole time we used thick padded moving blankets and was super careful not to scratch anything in the house.

The customer was happy. Her plan was to distress the look of the wood and then to seal it.

For me this was a huge learning project. I didn't make much money off of it. I made a bunch of "Rookie Mistakes". But none of this was the customer's fault, it was all mine. Last thing I wanted to do was change the originally quoted price halfway through the project. I want this customer to be a return client and refer me to other customers. So live with my mistakes and learn from them. My word is my bond!

What I need to do is get better at estimating projects. Here is what I need to do:

- Never quote a price to a prospective customer "on the fly"

- Figure out a set price for wood and stick to it

- Estimate labor time and have a set charge for it

- Avoid deliveries. But when you have to do it, charge for it

- Give the customer an estimate with everything broken down for them to see

Fun project, GREAT learning opportunity, the customer got a great deal, and we have the potential of repeat business or referrals. It's a win all the way around.

Leave a Comment

All comments are moderated.